Quartz Wafer Boat For Diffusion Of Wafer, Oxidation And Annealing Processing In Tube Furnace

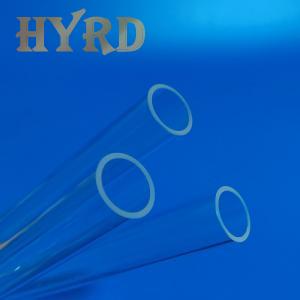

- Product Item : HYRD-QC03

- Category: Quartz Carriers

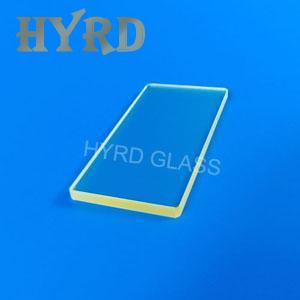

- Material: High purity quartz glass

- Type: 2”, 3”, 4”, 5”, 6”.

- Dimension: Standard and Customized

- Surface: Transparent

Quartz Wafer Boat For Diffusion Of Wafer, Oxidation And Annealing Processing In Tube Furnace

The quartz wafer boat is used in tube furnace. The upper limit of the working temperature of the quartz wafer boat can reach 1200 ℃, and it is specially designed for diffusion of wafer, oxidation and annealing processing in tube furnace. It can hold Ø2 ", Ø3", Ø4 ", Ø6" wafers.

Product Features:

Material: High purity silica glass

Dimension: According to requirement or standard

Surface: smooth

Color: Transparent

Process: Thermal process

Application: Diffusion of wafer in tube furnace

Available type: 2”, 3”, 4”, 5”, 6”...

Packing: Wooden box in export standard

Properties of Quartz Glass

1. High temperature resistance. The softening point temperature of quartz glass is about 1730°C, it can be used for a long time at 1100℃, and the higher temperature can reach 1450℃ in a short time.

2. Corrosion resistance. Except for hydrofluoric acid, quartz glass hardly reacts with other acids. Its acid resistance is 30 times that of ceramics and 150 times that of stainless steel. Especially the chemical stability at high temperature is unmatched by any other engineering material.

3. Good light transmission performance. Quartz glass has good transmittance in the entire spectrum from ultraviolet to infrared, and the transmittance of visible light is above 93%, especially in the ultraviolet spectrum, the maximum transmittance can reach more than 80.

4. Good thermal stability. Quartz glass has a small thermal expansion coefficient and can withstand severe temperature changes. When the quartz glass is heated to about 1100 ℃, it will not burst when placed in normal temperature water.

5. Quartz glass has good electrical insulation properties. The resistance value of quartz glass is equivalent to 10,000 times that of ordinary glass. It is an excellent electrical insulating material with good electrical properties even at room temperature.

Package

As our product is glass parts, which is fragile during transportation. We carefully do packing for each part. Optical paper, plastic foam, pearl cotton, plastic box etc, we try to protect parts by all means.

Logistics

For logistics, we support shipping by sea, air, or express. We help customer choose economic, safe and fast shipping method, which is suitable for customer requirements.

About Us

Beijing HYRD Photonics Co., Ltd established in year 2011. Our products mainly include quartz glass products, optical glass components, optical coating etc.

Quartz Glass Products Series:

Quartz tubes, quartz rods, quartz discs and substrates, CNC machined quartz glass parts, quartz glass instruments, quartz carriers, quartz rings, quartz cuvettes, quartz flow tubes, custom quartz parts, optical quartz glass components, etc.

Optical Glass Series:

Spherical single lens, achromatic lens, cylindrical mirror, toric mirror, mirror, window, prism, spectroscope, filter, grating, spherical / aspherical mirror, aspherical cylindrical mirror, spherical + cylindrical mirror, spherical + toric mirror, parabolic mirror, special-shaped optical parts, etc.

Optical coating series:

We provide a wide range of optical film systems, covering ultraviolet, visible, near-infrared, mid far infrared bands. The optical film serious includes AR coating, partial reflection film, metal high reflection film, medium high reflection film, beam splitting film, laser crystal film, infrared film, ultraviolet film, filter film, optical fiber film and other high-precision and difficult film serious.

We can produce according to customer’s requirement. With 11 years of professional glass processing experience, we have mastered various glass processing methods: glass punching, glass drilling, glass lapping, glass polishing, CNC glass machining etc.

Quality Guarantee

Honesty and trust are the foundation of the business. We achieve customer satisfaction with high-quality products and services through excellent production and continuous improvement!

The quartz wafer boat is used in tube furnace. The upper limit of the working temperature of the quartz wafer boat can reach 1200 ℃, and it is specially designed for diffusion of wafer, oxidation and annealing processing in tube furnace. It can hold Ø2 ", Ø3", Ø4 ", Ø6" wafers.

Product Features:

Material: High purity silica glass

Dimension: According to requirement or standard

Surface: smooth

Color: Transparent

Process: Thermal process

Application: Diffusion of wafer in tube furnace

Available type: 2”, 3”, 4”, 5”, 6”...

Packing: Wooden box in export standard

Properties of Quartz Glass

1. High temperature resistance. The softening point temperature of quartz glass is about 1730°C, it can be used for a long time at 1100℃, and the higher temperature can reach 1450℃ in a short time.

2. Corrosion resistance. Except for hydrofluoric acid, quartz glass hardly reacts with other acids. Its acid resistance is 30 times that of ceramics and 150 times that of stainless steel. Especially the chemical stability at high temperature is unmatched by any other engineering material.

3. Good light transmission performance. Quartz glass has good transmittance in the entire spectrum from ultraviolet to infrared, and the transmittance of visible light is above 93%, especially in the ultraviolet spectrum, the maximum transmittance can reach more than 80.

4. Good thermal stability. Quartz glass has a small thermal expansion coefficient and can withstand severe temperature changes. When the quartz glass is heated to about 1100 ℃, it will not burst when placed in normal temperature water.

5. Quartz glass has good electrical insulation properties. The resistance value of quartz glass is equivalent to 10,000 times that of ordinary glass. It is an excellent electrical insulating material with good electrical properties even at room temperature.

Package

As our product is glass parts, which is fragile during transportation. We carefully do packing for each part. Optical paper, plastic foam, pearl cotton, plastic box etc, we try to protect parts by all means.

Logistics

For logistics, we support shipping by sea, air, or express. We help customer choose economic, safe and fast shipping method, which is suitable for customer requirements.

About Us

Beijing HYRD Photonics Co., Ltd established in year 2011. Our products mainly include quartz glass products, optical glass components, optical coating etc.

Quartz Glass Products Series:

Quartz tubes, quartz rods, quartz discs and substrates, CNC machined quartz glass parts, quartz glass instruments, quartz carriers, quartz rings, quartz cuvettes, quartz flow tubes, custom quartz parts, optical quartz glass components, etc.

Optical Glass Series:

Spherical single lens, achromatic lens, cylindrical mirror, toric mirror, mirror, window, prism, spectroscope, filter, grating, spherical / aspherical mirror, aspherical cylindrical mirror, spherical + cylindrical mirror, spherical + toric mirror, parabolic mirror, special-shaped optical parts, etc.

Optical coating series:

We provide a wide range of optical film systems, covering ultraviolet, visible, near-infrared, mid far infrared bands. The optical film serious includes AR coating, partial reflection film, metal high reflection film, medium high reflection film, beam splitting film, laser crystal film, infrared film, ultraviolet film, filter film, optical fiber film and other high-precision and difficult film serious.

We can produce according to customer’s requirement. With 11 years of professional glass processing experience, we have mastered various glass processing methods: glass punching, glass drilling, glass lapping, glass polishing, CNC glass machining etc.

Quality Guarantee

Honesty and trust are the foundation of the business. We achieve customer satisfaction with high-quality products and services through excellent production and continuous improvement!