Schott BOROFLOAT® 33

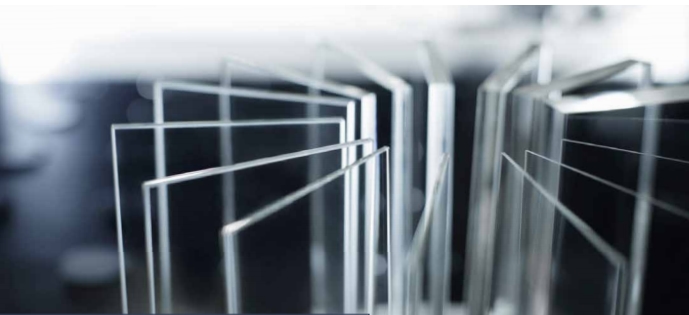

BOROFLOAT® 33 is floated borosilicate flat glass from Schott. Its superior quality and excellent

flatness combine with outstanding thermal, optical, chemical and mechanical features. The chemical composition and physical values of BOROFLOAT® 33 are in accordance with DIN ISO 3585 and DIN EN 1748 T1.

• Outstanding thermal resistance

• Exceptionally high transparency

• High chemical durability

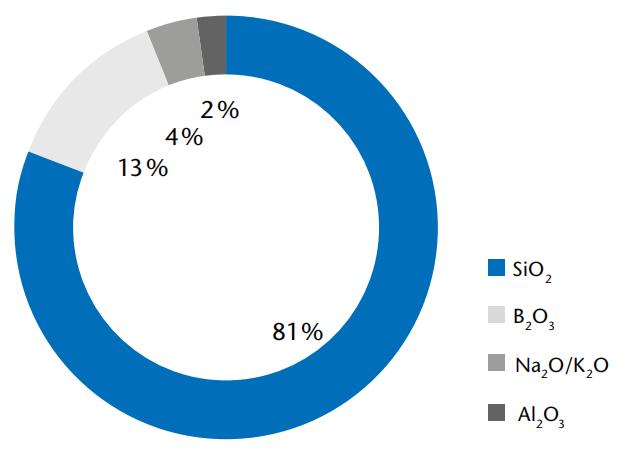

Chemical composition of BOROFLOAT® 33

* According to ISO 7991.

Chemical durability

Mechanical properties

Electrical Properties

Optical Properties

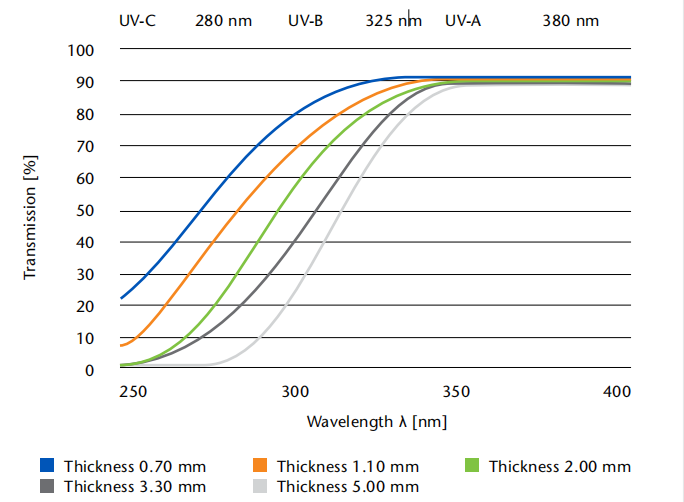

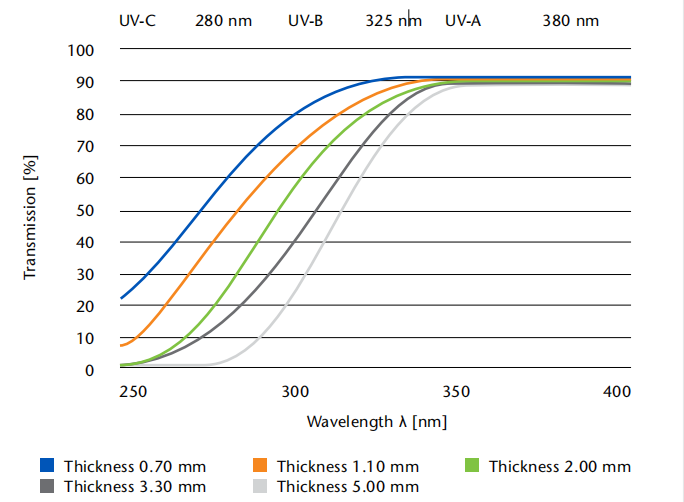

Transmission in UV range

BOROFLOAT® 33 is floated borosilicate flat glass from Schott. Its superior quality and excellent

flatness combine with outstanding thermal, optical, chemical and mechanical features. The chemical composition and physical values of BOROFLOAT® 33 are in accordance with DIN ISO 3585 and DIN EN 1748 T1.

Key Benefits:

• Excellent mechanical strength• Outstanding thermal resistance

• Exceptionally high transparency

• High chemical durability

Chemical composition of BOROFLOAT® 33

|

Coefficient of Linear Thermal Expansion (C.T.E.) α(20–300 ℃) |

3.25 x 10-6 K-1 * |

|

Transformation temperature Tg |

525 ℃ |

|

Annealing Point (1013 dPas) |

560 ℃ |

|

LITTLETON temperature/Softening point (107.6 dPas) |

820 ℃ |

|

Thermal conductivity λ (90 ℃) |

1.2 W/(m·K) |

|

Specific heat capacity cp (20–100 ℃) |

0.83 kJ/(kg·K) |

|

Maximum Operating Temperature |

|

|

For short-term usage (< 10 h) |

500 ℃ |

|

For long-term usage (≥ 10 h) |

450 ℃ |

Chemical durability

|

Hydrolytic resistance (according to ISO 719 / DIN 12 111) (according to ISO 720) |

HGB 1 HGA 1 |

|

Acid resistance (according to ISO 1776 / DIN 12 116) 1 |

1 |

|

Alkali resistance (according to ISO 695 / DIN 52 322) |

A 2 |

Mechanical properties

|

Density ρ (25 ℃) |

2.23 g/cm3 |

|

Young's Modulus E (according to DIN 13316) |

64 kN/mm2 |

|

Poisson's Ratio µ (according to DIN 13316) |

0.2 |

|

Knoop Hardness 0.1/20 (according to ISO 9385) |

480 |

|

Bending Strength σ(according to DIN 52292 T 1) |

25 MPa |

|

Impact resistance The impact resistance of BOROFLOAT® 33 depends on the way it is fitted, the size and thickness of the panel, the type of impact involved, presence of drill holes and their arrangement as well as other parameters. |

|

Electrical Properties

|

Dielectric Constant ℇr (1 MHz & 25 ℃) |

4.6 |

|

Loss Tangent tanδ (1 MHz & 25 ℃) |

37 x 10-4 |

|

Specific Volume Resistance in Ω cm Log ρ 250 ℃ 8.0 Log ρ 350 ℃ 6.5 |

|

Optical Properties

|

Refraction index (nd (λ587.6 nm)) 1.471 |

|

Dispersion (nF - nC) 71.4 x 10-4 |

|

Low inherent fluorescence and solarisation tendency |

Transmission in UV range