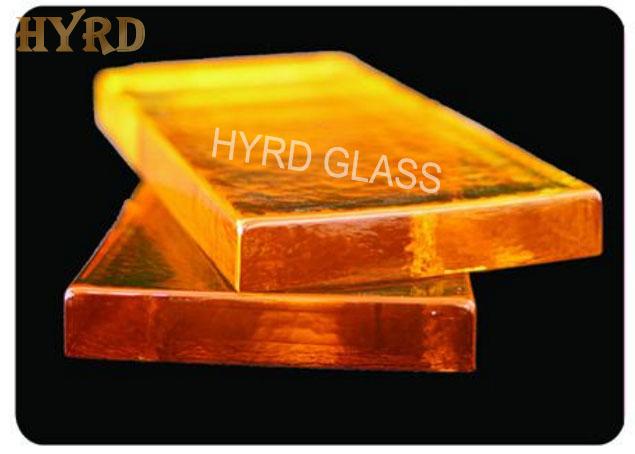

Samarium Doped Glass

Samarium Doped Glass 5%, Samarium Doped Glass 10%, Samarium Doped Glass 20%, Samarium Doped Glass 30%. We can custom produce the different percentage of Samarium Doped Glass.

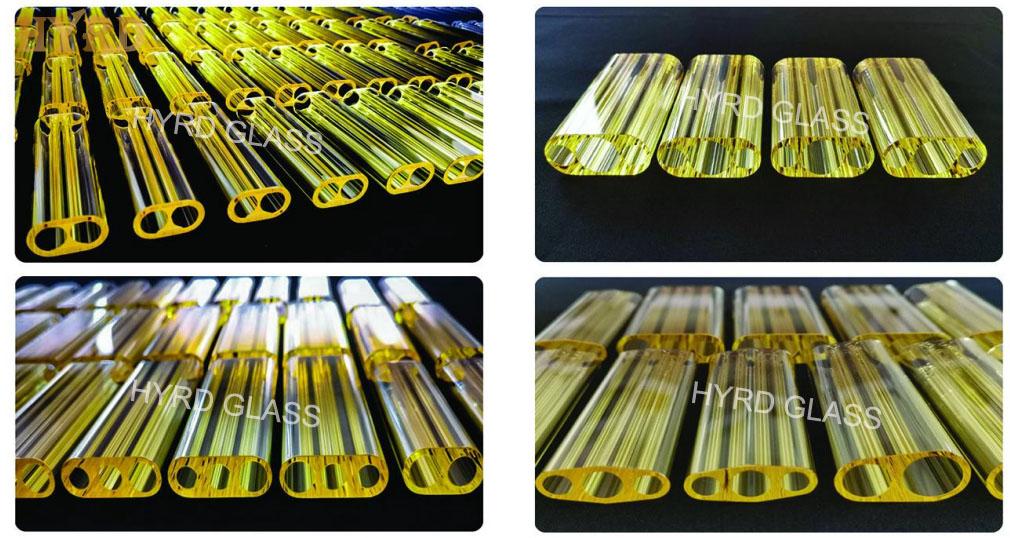

The samarium doped glass is new type of dual end cutoff focusing cavity glass, which is used in laser emitter components. The glass is processed through optical cold processing to form a focusing cavity (also called as laser flow tube). After processing, the chemical strengthening is necessary to increase the laser flow tube strength. The function of the focusing cavity in the laser module is to concentrate the light energy emitted by the Krypton lamp onto the laser rod, which is then transformed into a 1064nm continuous laser through the energy level transition of the laser rod.

The absorption of ultraviolet light in a krypton lamp by a laser rod will generate color centers, making the laser unable to function properly; In addition, the radiation of 1064nm light in the Krypton lamp consumes a portion of the particles in the upper level of the laser, reducing the output of the laser, known as the pump out effect.

The samarium doped glass can absorb ultraviolet light generated by krypton lamps, as well as 1064nm near-infrared light. It can effectively improve the reliability, lifespan, and laser radiation efficiency of laser components.

Applications of Samarium Doped Glass

Flat plates, close fitting cylindrical sleeves, cylindrical water jackets, etc. These materials can be chemically strengthened to increase their mechanical strength and thermal shock resistance fourfold. After optical cold processing, the material can be produced as flow tubes which used as filter media in the laser cavity of flash lamp pumped solid-state laser systems

Please contact us for more information.