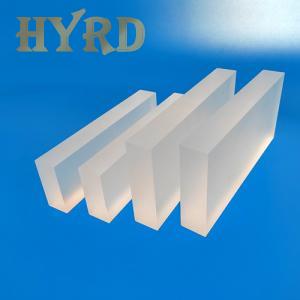

Solid-state Yellow Glazed Alumina Ceramic Laser Reflectors

- Product Item : HYRD-AC009

- Category: Ceramic Laser Reflectors

- Material: Alumina ceramic

- Surface: Yellow Glaze

- Tolerance: 0.5mm

- Application: Solid state lasers

Solid-state Yellow Glazed Alumina Ceramic Laser Reflectors

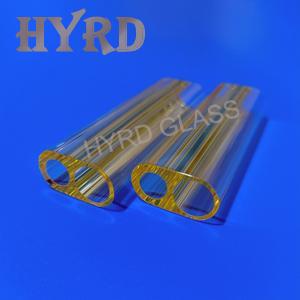

When working in a laser cavity, ultraviolet light can cause harmful color centers in the laser crystal. The yellow glazed ceramic reflectors can effectively absorb ultraviolet rays, preventing the temperature of the crystal from being too high, which is beneficial for the service life of the crystal. In the ultraviolet band, the reflectivity of the yellow glaze cavity decreases by about 50% compared to the wavelength corresponding to white glaze. Highly reflective and UV absorbing ceramic glazes can significantly improve the shortcomings of ordinary ceramic spotlight cavities, with characteristics such as resistance to strong laser irradiation, high insulation, corrosion resistance, easy cleaning, and UV absorption.

Physical Characteristics:

|

Color |

Yellow |

|

Density |

3.1g/cm3 |

|

Pore rate |

22% |

|

Bending strength |

170MPa |

|

Thermal expansion coefficient |

7.9 × 10-6/C (200-500 ℃) 9 × 10-6/C (200-1000 ℃) |

Applications of ceramic laser cavity:

- Industrial laser cutting and welding systems

- Military laser systems

- Scientific research lasers

- Medical laser equipment

- Space-based laser communications