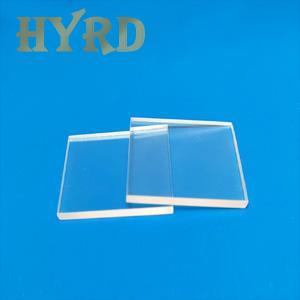

Frost Quartz Ring for OPTORUN Optical Coating Machine

- Product Item : HYRD-F007

- Category: Quartz Rings

- Material: High purity quartz glass

- Purity: 99.99%

- Surface: Frost

- Application: OPTORUN Optical Coating Machine

Frost Quartz Ring for OPTORUN Optical Coating Machine

Frost quartz ring is used as one of the spare parts for optical coating machine.High purity gas refined fused silica glass is widely used as coating material for mirror multilayer coating and anti reflection coating due to its high purity, colorless transparency, few bubbles and impurities, high transmittance of ultraviolet and visible light, and excellent thermal and chemical properties of its SiO2 content of more than 99.99%. We are able to produce, process, and supply quartz glass materials for coating in various shapes and specifications, including granular, sheet, circular, spherical, cylindrical, etc. At the same time, we also produce quartz glass components for supporting vacuum coating machine equipment.

Regular Size of Quartz Material for Optical Coating (mm)

Shape

Dimension (mm)

Granular

<1 1~3 3~5

Sheet

Φ15.5X10 Φ30X15 Φ50X5 Φ60X 7

Ring

Φ212/Φ170X15 Φ300/Φ230X 15 Φ335/Φ265X15

Ball

Φ5, Φ3

Cylindrical

Φ5X5, Φ3X3

Product

Dimension (mm)

Quartz Crucible/Quartz Chamber

Φ196X63, Φ286X104

Quartz Class Sputtering Target Material

1016X136X6, Φ355X12

Quartz glass window

725X320X28, 360X320X 16

K9 Optical Glass Monitoring Sheet

Φ160/Φ40X2, Φ142/Φ80X1.8

Mechanical Properties

|

Material |

Quartz Glass |

|

Density |

2.203g/cm3 |

|

Compressive Strength |

1100Mpa |

|

Bending Strength |

67Mpa |

|

Tensile Strength |

48.3Mpa |

|

Poisson's Ratio |

0.14~0.17 |

|

Young’s Modulus |

72000Mpa |

|

Rigidity Modulus |

31000Mpa |

|

Mohs Hardness |

5.5~6.5 |

Thermal Properties

|

Deformation Point |

1280℃ |

|

Softening Point |

1680℃ |

|

Annealing Point |

1210℃ |

|

Specific Heat (20~350℃) |

670J/kg.℃ |

|

Thermal Conductivity (20℃) |

1.4W/m.℃ |

|

Coefficient of thermal expansion |

5.5×10-7cm/cm.℃ |

|

Hot Work Temperature |

1700~2000℃ |

|

Short-term Use Temperature |

1300℃ |

|

Long-term Use Temperature |

1100℃ |

Electrical Properties

|

Resistivity |

7×107Ω.cm |

|

Dielectric Strength |

250~400Kv/cm |

|

Dielectric Constant ε |

3.7~3.9 |

|

Dielectric absorption coefficient |

<4×104 |

|

Dielectric loss coefficient |

<1×104 |