Candela Laser Head Assemblies

- Product Item : HYRD-C006

- Category: Laser Head Cavity

- Reflectance Material: Alumina ceramic

- Wavelength: 755/2940nm

- Application: Medical Laser Equipment

- Minimum Order Quantity: Negotiable

Candela Laser Head Assemblies

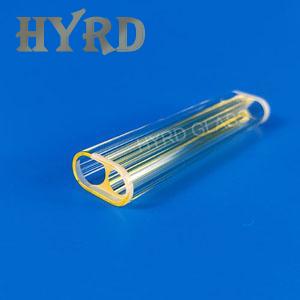

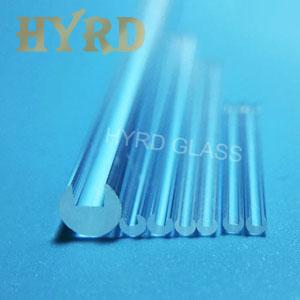

The Laser head assembly is composed of ceramic reflector, quartz triple bore, quartz flow tubes.The body of the ceramic reflector is prepared with purity 99% alumina Al2O3. The body is fired at appropriate temperature to retain proper porosity and proper body strength. The surface of the reflector is fully coated with high-reflectivity ceramic glaze technology. Compared with the gold-plated reflector, the major advantage is that its service life is extremely long and the reflection characteristic is diffuse reflection. The ceramic laser reflector is widely used in laser welding machines, laser cutting machines, laser marking and medical industries. We can customize manufacture a variety of ceramic cavities according to drawings.

Main Characteristics of Ceramic Laser Reflectors:

1. The surface is fully glazed for high reflectivity and easy cleaning;2. The reflectivity reaches 98% at the wavelength of 600-1000nm;

3. The reflectivity exceeds 96%at the wavelength of 400-1200nm;

4. The green body has appropriate porosity and high-strength characteristics.

Product Features

• Uniform reflective material• High reflectivity

• Diffuse reflection

• Environment protection

• High laser power

• Long service life