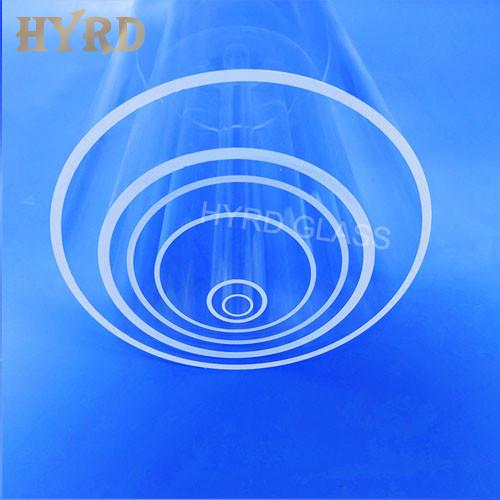

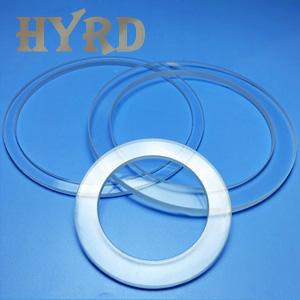

Fused Quartz Tubing Various Sizes

- Product Item : HYRD-A017

- Category: Quartz Tubes

- Material: Fused quartz glass

- Size: Various Sizes

- Stock: Available

- Minimum Order Quantity: Negotiable

Fused Quartz Tubing Various Sizes

Fused quartz tubing is a tubular material made of quartz, which has excellent chemical stability, mechanical strength, and optical properties. Quartz tubes are widely used in fields such as fiber optic communication, optical instruments, semiconductor manufacturing, and chemical experiments. In the field of quartz tube processing, it mainly includes the processing, cutting, polishing, drilling and other processes of pipes to meet the needs of different industries for quartz tubes.

We can process quartz tubes in various ways, and the process usually includes the following steps:

1. Tubes cutting: Quartz tubes are usually cut by using laser cutting machines or diamond cutting machines. The cutting process requires ensuring the flatness and dimensional accuracy of the cutting edge to ensure the quality of subsequent processing.

2. Tubes polishing: The cut quartz tube needs to be polished on the surface to remove burrs and smooth the surface left by cutting. Common polishing methods include mechanical polishing and chemical polishing, which can achieve different surface roughness and smoothness requirements through different polishing processes.

3. Drilling of tubes: In some applications, it is necessary to drill holes in quartz pipes, usually using laser drilling machines or machining centers. The purpose of drilling holes is to form pathways or holes inside the pipe to meet the needs of different applications.

4. Tubes splicing: In some special applications, multiple sections of quartz pipes need to be spliced, usually using methods such as fluororesin glue or high-temperature welding for tube splicing. The quality of splicing has a significant impact on the performance and stability of the entire pipeline.

5. Pipe inspection: It is the inspection of processed quartz pipes, usually including size measurement, surface quality inspection, optical performance testing, and other contents. Strict testing can ensure that the quality of quartz tubes meets customer requirements.

Fused quartz tubing is a tubular material made of quartz, which has excellent chemical stability, mechanical strength, and optical properties. Quartz tubes are widely used in fields such as fiber optic communication, optical instruments, semiconductor manufacturing, and chemical experiments. In the field of quartz tube processing, it mainly includes the processing, cutting, polishing, drilling and other processes of pipes to meet the needs of different industries for quartz tubes.

We can process quartz tubes in various ways, and the process usually includes the following steps:

1. Tubes cutting: Quartz tubes are usually cut by using laser cutting machines or diamond cutting machines. The cutting process requires ensuring the flatness and dimensional accuracy of the cutting edge to ensure the quality of subsequent processing.

2. Tubes polishing: The cut quartz tube needs to be polished on the surface to remove burrs and smooth the surface left by cutting. Common polishing methods include mechanical polishing and chemical polishing, which can achieve different surface roughness and smoothness requirements through different polishing processes.

3. Drilling of tubes: In some applications, it is necessary to drill holes in quartz pipes, usually using laser drilling machines or machining centers. The purpose of drilling holes is to form pathways or holes inside the pipe to meet the needs of different applications.

4. Tubes splicing: In some special applications, multiple sections of quartz pipes need to be spliced, usually using methods such as fluororesin glue or high-temperature welding for tube splicing. The quality of splicing has a significant impact on the performance and stability of the entire pipeline.

5. Pipe inspection: It is the inspection of processed quartz pipes, usually including size measurement, surface quality inspection, optical performance testing, and other contents. Strict testing can ensure that the quality of quartz tubes meets customer requirements.